Content

Innovation in Scotland’s National Retrofit Centre: External Systems

Scotland’s National Retrofit Centre will be a standout example of how local natural resources, systems, and innovations can be utilised in retrofit. In addition to contributing to the final striking appearance, the external systems used on the building envelope will deliver strong thermal performance while also acting as a carbon sink.

Why include these systems?

Every retrofit decision must carefully balance reducing energy demand with the embodied carbon of materials and construction processes.

The selected systems prioritise ultra-low embodied and operational carbon, support local supply chains, and showcase the diverse materials, processes, and solutions available both locally and at BE-ST. Incorporating sustainably sourced timber and ultra-low carbon bricks, the building’s external envelope is designed to capture more carbon than it emits over its lifecycle.

Offsite manufacturing and circular design principles are integral to delivering the building envelope efficiently. Without these local, low carbon solutions, the project's overall carbon footprint would be significantly higher, and the speed and effectiveness of delivery greatly reduced. Here, we highlight the suppliers, manufacturers, and products shaping the external side of the retrofit.

Cross laminated timber panels - Ecosystems Technologies

A significant element of the building envelope will be the cross laminated timber (CLT) panels, which Ecosystems Technologies is crucial to delivering. Their buildings are designed to showcase the beauty and versatility of homegrown mass timber solutions.

Key features and benefits

CLT delivers on innovative design, speed, cost and resource efficiency, health and wellbeing, and offers a low carbon, sustainable alternative to traditional building materials. Furthermore, in many cases, the streamlined construction process of mass timber offers 30-50% construction faster than conventional methods.

Installation

From the factory located at BE-ST's Campus, and working in partnership with the Clark Contracts delivery team, Ecosystems are manufacturing the Centre’s new wall panels from Scottish homegrown timber, to highlight Scottish resources, innovation, and the manufacturing capabilities at the factory at BE-ST.

Gill Henry, Director of Operations at Ecosystems says: “With a long track record of close collaboration with BE-ST, Ecosystems is delighted to be partnering with BE-ST on Scotland’s National Retrofit Centre. The momentum is growing for more sustainable ways to deliver retrofit. Our involvement ensures that incorporation of the homegrown product sits at the heart of this challenging project, targeting the use of new materials, digital design and innovative manufacturing techniques. Capturing the learning as we go, the project will make significant inroads into demonstrating how industrial buildings can be transformed and boundaries on retrofit can be pushed for wider roll out.”

Timber cladding - Russwood

Russwood are providing timber cladding for the retrofit, combining design excellence with minimal environmental impact to create sustainable buildings.

Key features and benefits

Thermopine® and Lunawood are timbers with enhanced stability and durability, produced by thermally modifying Scandinavian grown Scots Pine. The advanced, highly controlled modification process results in a reduction of the wood’s tendency to shrink and swell whilst reducing its vulnerability to wood destroying organisms.

Installation

The cladding will be installed on the exterior of the building. The new walls are being constructed offsite and finished with the timber cladding from Russwood. Reducing material wastage and improving efficiency through increased accuracy and reduced man hours, working off site also negates the need for working at height and ensures progress is not hampered by inclement weather over winter.

Claire Howie, Marketing Director at Russwood says: “Russwood are delighted to support Scotland’s National Retrofit Centre and contribute our products to this showcase retrofit project. This collaboration demonstrates how design excellence can be achieved while minimising environmental impact to create beautiful, sustainable buildings. As retrofitting emerges as the future of sustainable construction, the Retrofit Centre will play a pivotal role going forward.”

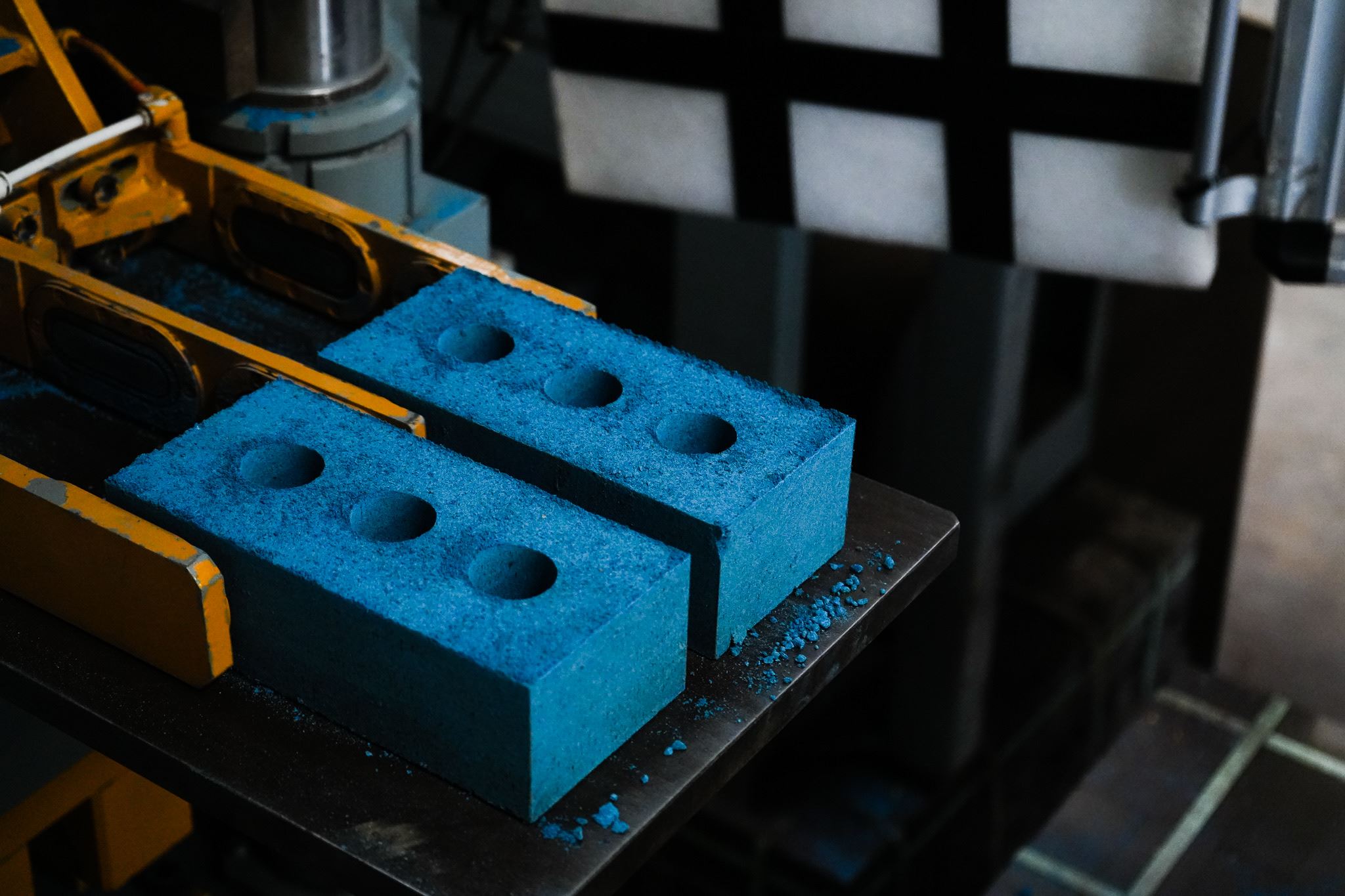

Recycled bricks - Kenoteq

The sustainable ultra-low carbon K-Briq from Kenoteq will play a pivotal part in the retrofit of Scotland's National Retrofit Centre’s façade.

Key features and benefits

The K-Briq is supporting local supply chains in this project. Made from over 95% recycled materials all from within a 30 mile radius of the Retrofit Hub, the K-Briqs used in this project have diverted more than 6.3 tonnes of local construction and demolition waste from landfill. Additionally, the K-Briq boasts the lowest embodied carbon of any brick in the market currently, significantly reducing the project's environmental impact. It is also fully tested by the British Board of Agreement (BBA), and meets Building Standards, with a top-level durability rating (F2), a highly competitive compressive strength of 29N/mm2 and A class resistance to fire rating.

Installation

The product is being used as a façade material for Scotland’s National Retrofit Centre, as a plinth façade providing a striking contrast against the building’s dark cladding. The 3,000 K-Briqs are saving 6.3 tonnes of local construction and demolition waste from landfill and are saving the environment 1.3 tonnes of CO2e compared to if traditional clay bricks had been used in their place.

Andrew Holt, Chief Executive Officer at Kenoteq says: “We are delighted to supply the K-Briq to support Scotland’s National Retrofit Centre as a living centre for best practice at a time when retrofit needs to be showcased as the most cost-efficient and sustainable means to the country’s future build programme, and net zero targets.

“As a new Scottish-based green economy manufacturing company, supported in its earlier stages with R&D funding and investment from the public, university and private sectors, it seems apt that Scotland’s National Retrofit Centre is the K-Briq’s first flagship exterior project in Scotland post-certification. We are delighted the K-Briq will become part of the country’s learning, demonstration and sharing of deep retrofit, and we will use this platform to build the company’s presence in the sector and as a high performing low carbon and sustainable retrofit solution.”