Mass Timber Centre of Excellence

Accelerating UK-grown mass timber adoption across the UK through innovation, manufacturing, and research.

A centre of excellence for mass timber innovation, manufacturing & research.

This cutting-edge facility, housed at BE-ST’s Innovation Campus, exists to support industry by accelerating the adoption of homegrown mass timber solutions, fostering sustainability, and strengthening local economies.

By adopting UK-grown mass timber in construction at scale, we could strengthen the forestry and timber industry, create jobs, reduce reliance on imports, increase sustainable delivery of the built environment and reduce carbon emissions generated by the construction sector.

Shaping the future of timber construction

By scaling up the use of mass timber, the UK can transition towards a built environment that is lower in embodied carbon, more cost-efficient, locally sourced, higher-quality and sustainable.

The Centre offers a number of services:

Mass timber manufacturing: Full-scale production using the UK’s most advanced equipment.

Systems design support: Collaborative research with industry and academic experts.

Consultancy services: Guidance on product approvals, regulations, and manufacturing processes.

Timber processing: Partnering with trusted experts for felling, grading, kilning, and planing.

Training & skills development: Hands-on workshops to upskill the construction workforce.

Access the UK’s most advanced mass timber manufacturing equipment.

With £1.5 million invested in state-of-the-art equipment, the Centre is home to the most advanced mass timber production facility in the UK. It offers full-scale production capabilities for various mass timber products, including:

Cross Laminated Timber (CLT)

Nail Laminated Timber (NLT)

Glue Laminated Timber (Glulam)

Glued Laminated Timber Panels (GLT-P)

Nailed Cross Laminated Timber (NCLT)

At the heart of the Centre’s operations is the largest commercially available CNC machine in the UK, providing unparalleled precision and efficiency in timber manufacturing. The factory is anticipated to have an annual manufacturing output capacity of approximately 8,000m³ once fully operational.

Uniteam Extra BM3 CNC Machining Centre

The Uniteam Extra BM3 CNC machine is engineered for high-precision processing of large-format engineered timber panels and beams. It delivers speed, flexibility, and consistent performance, making it ideal for complex machining tasks. Its advanced configuration supports intricate operations with exceptional accuracy, while ensuring safe and efficient workflow.

-

The CNC Machine features a 5-axis milling head with spindle, a 3-position tool changer for large tools, and a blade magazine holding 50–850mm saw blades. Ideal for cutting and profiling timber panels, it offers precision and efficiency, fully integrated with advanced CAD/CAM software for seamless design-to-production workflow.

BE-ST’s CNC machine, is one of the only offerings of its kind in the country and has the ability to cut and profile engineered timber components up to 400(D)x3000(W)x13500(L)mm.

Working with qualified operatives, BE-ST has the capability to process a wide range of wood-based panel and beam products. This includes everything from mass timber components—such as cross-laminated timber (CLT) and glue-laminated timber (glulam)—to the post processing of bespoke elements for stage scenes, exhibition sets, and prototyping. Our skilled team ensures high-quality output for both structural and creative applications.

-

Ability to process large format timber products and components.

Cutting curved sections, forming openings and service penetrations accurately.

Surface profiling for service runs, service boxes, checks, rebates, notches.

Enhanced health and safety with the ability to cut with precision, accuracy and speed.

Vacuum press

Our vacuum press is the only one of its kind in the UK and offers users the opportunity to create a range of panel products through the consistent and efficient vacuum process. Designed for optimal performance, the vacuum press offers exceptional planarity and uniformed 9.5 t/m2 pressure, guaranteeing a high-quality finished product.

-

Capable of processing a range of panel types and sizes our Vacuum Press offers exceptional flexibility in what you can produce.

The low investment costs associated with our vacuum press will enable your organisation to take a gradual approach to CLT and panel production in general. The low automation in the early stages of development can be increased as demand for your product rises within the market.

Organisations of all types can utilise the vacuum press. Whether you are a large-scale building company or a small family run organisation looking to launch innovative and new products, our Vacuum Press can enable your organisation to grow and reach new markets.

-

Versatility: The vacuum press allows users to create a range of products including cross laminated timber (CLT) panels, box beams, SIP panels, 3D formed panels and more.

Quality & consistency: The potential to produce CLT panels suitable for non-visible and visible finished surfaces in a consistent manner.

Flexibility: Capable of handling various panel shapes and sizes: maximum panel width 3.0m, maximum panel length 13.0m, maximum panel height 300mm.

Unique: Only one of its kind in the UK.

Glulam press

The Huang Hai Glulam press is a hydraulic machine used to produce glued laminated timber (GLT) beams and panels. It delivers consistent, uniform pressure across timber laminations, ensuring strong adhesive bonds and high structural performance. Its automated operation enhances efficiency and product quality in engineered timber manufacturing.

-

The Glulam Press can be used to manufacture both structural and non-structural GLT components, including beams, posts, and architectural elements. In conjunction with our other timber pre- and post-processing equipment, it can produce components up to 6000mm x 1300mm x 300mm.

Suitable for various timber species, the press enables precise application of pressure, in line with the manufacturing requirements for glued laminated timber components. Automation reduces manual handling, ensures consistent bonding quality, and significantly increases production throughput compared to traditional cramping methods. This capability supports efficient, high-quality fabrication of engineered timber elements for a range of construction applications.

-

Produces high-strength, durable glued laminated timber (GLT) suitable for structural applications.

Delivers uniform pressure to ensure consistent adhesive bonding across all laminations.

Minimises manual clamping, reducing labour requirements and production time.

Enhances precision and overall quality of finished GLT components.

Supports a wide range of timber sizes and configurations for versatile use

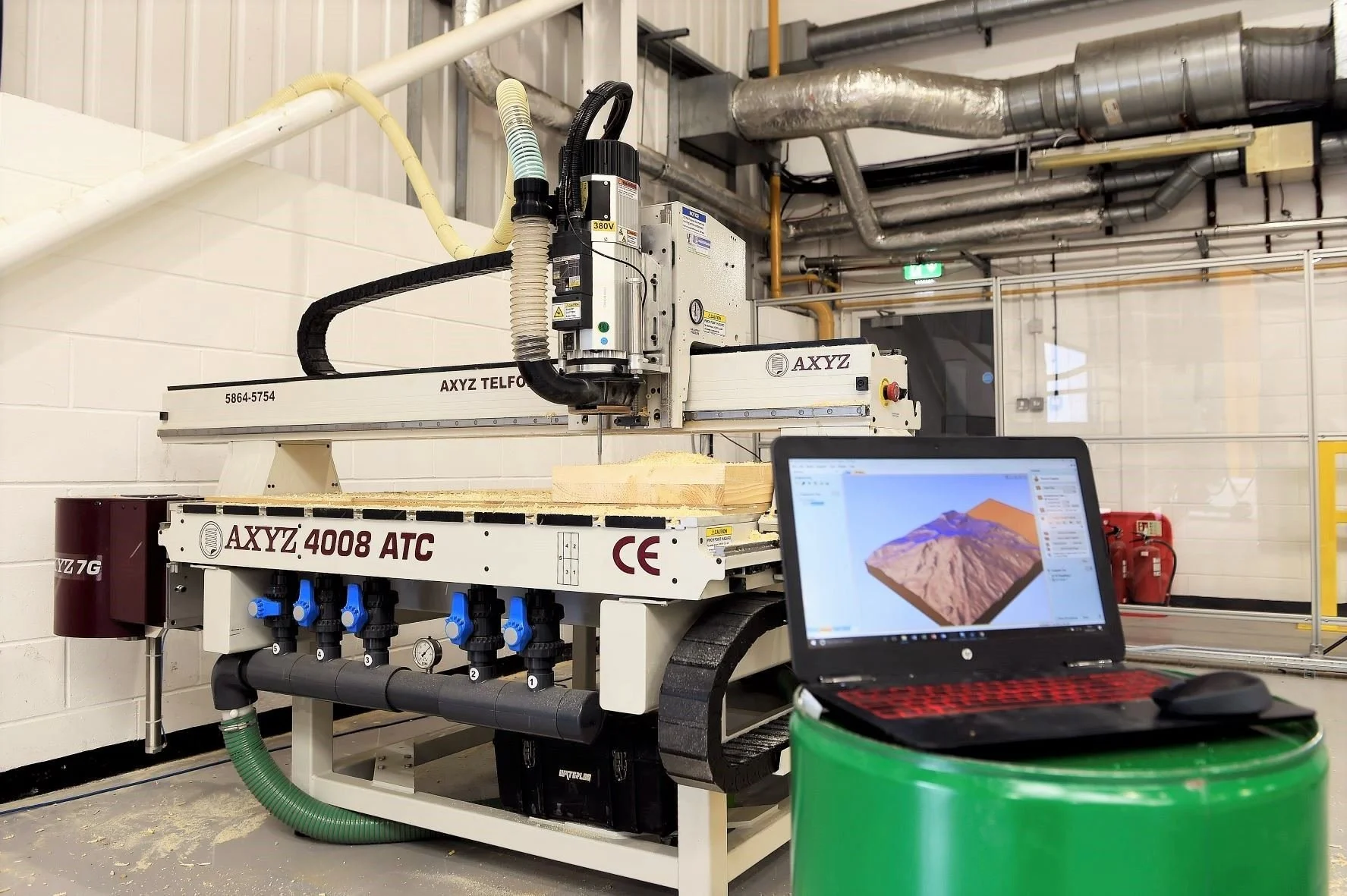

CNC router

Our CNC router offers a flexible, automated solution for a range of manufacturing needs. This machine enables organisations to reduce labour costs, create less waste and improve operating capacity and efficiency. Utilising the latest technology, users can experience a precise, safe and user-friendly experience for a range of projects.

-

Our CNC router is capable of processing timber, composites, laminates and non-ferrous metals, among other materials. This creates flexible solutions for processing applications such as sheet material cutting, cladding panels, 3D profiling, general woodworking, exhibition stands, interiors, plastic fabrication, metal fabrication, foam modelling and more.

-

Automation: the automated CNC Router can accurately repeat tasks fed from a digital design or CAD model without the need for manual input.

Accuracy: this state-of-the-art technology allows for intricate processes to be performed with ease. If the design is drawn to the correct scale measurements, then the router can efficiently execute the task.

Safety: fitted with all relevant safety features and through remote operation (minimal reliance on manual input) this machine offers a higher quality product with reduced risk to the operator.

Reduced labour costs: The automated nature of this machine allows constant and reliable production from a single operator.

Flexibility: in built memory provides the ability for this machine to access numerous programmed operations at the click of a button meaning your organisation can focus on a range of projects simultaneously.

-

Download our technical specification sheet here.

Four-sided timber planer

Our four-sided timber planer utilises the latest technology to quickly and accurately plane timber beams down to size and ensures a flat, even finish and perfectly right-angled sections.

-

The machine setup is fully automated so that the operative only needs to enter the desired dimensions and let the planer do the rest.

For many operations it is essential for timber to be planed, whether there is a requirement for all four sides to be planed or require perfect right angles after the timber has been processed, our four-sided timber planer offers a versatile approach.

Particularly beneficial to the production of engineered wood products such as CLT or Glulam, which rely upon the component parts being even and square.

-

Automation: A single operative can efficiently and accurately produce perfectly planed timber repeatedly. The intuitive interface enables operatives to produce high quality finished timber.

Safety: With an intuitive control system operatives will never be in danger throughout the timber plane process.

Adaptability: Capable of changing finished dimensions settings quickly with the added benefit of clear visualised laser guidance indicating finished section size.

-

Download our technical specification sheet here.

Optimising saw

The optimising saw offers efficient measuring, cutting and marking of timber members. Working in conjunction with offsite construction processes, the reliability, speed, and accuracy of the preparation of raw materials is essential.

-

Our optimising saw offers high-speed timber processing utilising automatic calculation from electronic cutting lists.

Primarily used for cutting solid timber and engineered wood products, beams to length (and for defect cutting) through a quick and accurate process.

-

Automation: A single operative can efficiently, safely and accurately process large volumes of timber.

Flexibility: Our optimising saw is compatible with a wide range of material dimensions.

Accuracy: The state-of-the-art software and technology enables operatives to produce high quality products every time.

Reduced waste: Optimised cutting of timber ensure offcuts are kept to a minimum.

-

Download our technical specification sheet here.

Handheld 3D scanner

Our handheld 3D scanners capture real world data to convert into a digital 3D model. The ability to scan any material, surface, or profile creates a base model for further development. This negates the need for complex 3D CAD modelling or extensive measurement and mapping of irregular surfaces.

-

3D scanning allows you to use existing physical objects to conceptualise an idea or create a starting point for modelling in CAD (Computer Aided Design).

Our handheld 3D scanners can be used for consumer and commercial applications in manufacturing, engineering, design, development, testing and human form acquisition.

They can also be used for: 3D printing and rapid prototyping, 3D inspection, and reverse engineering among others.

-

Prototyping: Create an instant base for further development.

Accuracy: Up to 0.05mm single shot accuracy allowing detailed mapping within a scan.

Replication: The ability to match existing profiles and produce replacement or repaired items such as traditional cornicing or skirting.

360 imaging laser scanner

Our tripod mounted 3D scanner captures real world data to convert into a digital 3D model.

The 360 imaging laser scanner allows the user to capture point cloud and full-colour images at room and building scale.

The scanner also includes thermal imaging capabilities.

-

Using real site data allows accurate design, manufacture and installation.

Convenient operation at the touch of a button, scanning can be used for consumer and commercial applications in manufacturing, engineering, design, development and testing.

3D scanning can be used for: site mapping, in-progress inspection, Facilities Management, digital twin creation and error/fault detection.

-

Fast and simple operation

Portable and tablet based processing

Inbuilt image documentation and storage.

Wall panel saw

The Striebig wall saw is a vertical panel saw that is designed for the accurate and efficient cutting of sheet material, including OSB, Ply, Fermacell, MDF, Plastics and rigid insulation materials.

-

The Striebig Compact 4164 is a high-precision vertical panel saw, ideal for safe, efficient mass-cutting of sheet materials. With a cutting range of 3100 x 1600 x 60 mm and a robust, self-supporting frame, it delivers consistently accurate, splinter-free cuts—even with irregular panel sizes.

Designed to support flexible production workflows, operators can easily adjust for vertical, horizontal, or angled cuts without compromising finish quality. The powerful 3.9 kW motor handles plywood, MDF, OSB, and composite panels with ease. Its ergonomic vertical layout and enclosed blade ensure safe handling of large panels, while integrated dust extraction supports clean, low-dust operation.

-

High precision and repeatability which ensures accurate cuts with minimal material waste.

Versatile cutting that handles timber, plywood, OSB, MDF, and other sheet materials.

Improved safety with reduction in manual handling and the supporting of safer cutting of panels.

Reduced operator fatigue as ergonomic setup supports prolonged use with less strain.

Enhanced productivity can speed up cutting processes compared to manual methods

Virtual reality headset

The virtual reality headset offers users a fully immersive experience that allows for targeted training, client presentations, design idea dissemination and guided work instructions. The virtual reality enables discussion and development of future and potential projects in a photo realistic setting.

-

Like AR technology the virtual reality headset helps users efficiently interpret physical and digital information, and the spatial relations between them.

The VR setup can be used to visualise proposed developments or new systems of work.

Based in factory conditions, this offers the ability to alternate between virtually created content and real-life demonstration.

-

Contextual representation: Digital designs can be realised and represented in a virtual context. Immersed in a digital environment, users can interact, interpret and understand a concept or idea in a 1:1 environment.

Training: Potential to train operatives with virtual and unique environments which represent the actual process.

Safety: The ability to represent dangers or difficult environments allows operatives the opportunity to experience varied processes and techniques in a controlled situation.

3D Visualisation: Users can visualise 3D designs/ drawings and engage and interact with the data.

Reduced costs: Capable of simulating a range of features within a project prior to its development enables users to accurately choose the best solutions and prevent any issues later in development.

-

Download our technical specification sheet here.

Augmented reality suite

We have a number of augmented reality headsets including the Trimble XR10 Hololens 2 for site work and the Hololens 1 for office use.

Interacting with holograms in mixed reality enables you to visualise and work with digital content as part of the real world.

-

Like VR technology, our augmented reality suite helps users efficiently interpret physical and digital information, and the spatial relations between them.

In construction, this opens new opportunities for a range of applications including augmenting real objects, interaction with graphics overlaid on real life objects and spaces, data visualisation, guided work instructions and training and guidance through a remote expert.

-

Contextual representation: Digital designs can be realised and represented in a physical context. Displayed in real time users can interact, interpret and understand a concept or idea in a 1:1 environment.

Training: Potential to train operatives with holographic environments which represent the actual process.

Safety: The ability to represent dangers or difficult environments allows operatives the opportunity to experience varied processes and techniques in a controlled situation.

3D Visualisation: Users can visualise 3D designs/ drawings and engage and interact with the data.

Collaboration: Remote viewing features enable multiple parties to share and interpret information simultaneously.

-

Download our technical specification sheet here.

Multi-material 3D printer

The large format multi-material 3D printer offers an industrial scale build volume meaning you can create 3D models faster and larger. The material quality allows working structural prototypes to be created and developed. The extended build volume means scale models can be larger and printed in one batch.

-

3D printing is ideal for staged prototyping and product development. Working prototype models allow direct comparison and testing with the physical environment.

The multi-material 3D printer can complete a wide range of applications for both large and small prototypes for a variety of applications including over-moulded parts, multi-material assemblies, rubber-like components, dies, jigs, fixtures, brackets among many others.

-

Versatile: Capable of printing a range of material finishes.

Volume: The large build plate is ideal for industrial sized components or larger batch production of smaller items.

Speed: Faster than traditional prototyping processes.

Definition: The high accuracy of the print allows fine and detailed features or models.

Reduced costs: 3D printing requires low initial capital investment. Tooling and moulds are not required to create new products.

-

Download our technical specification sheet here.

Explore our case studies in homegrown mass timber and offsite manufacturing.

COP26 Homegrown Demonstrator

Would you like to integrate timber in your projects or build using offsite construction methods?